Silica sand, also known as quartz sand, is a common material used in foundries for various purposes. Foundries are industrial establishments where metal casting processes occur, primarily producing components for various industries such as automotive, construction, and engineering. The use of silica sand in foundries serves multiple functions, including:

- Mold making: Silica sand is mixed with clay, water, and other additives to create a mold or a core. The mixture is shaped around a pattern and allowed to dry, forming a strong and durable mold that can withstand the high temperatures involved in the metal casting process.

- Core making: In addition to mold making, silica sand is also used to create cores. Cores are used to create internal shapes or hollow spaces within the final cast product. They are made by packing sand around a core box, which is then removed, leaving the desired internal shape.

- Filtration: Silica sand is used in filtration systems to remove impurities, such as dirt and other contaminants, from the molten metal before it is poured into the mold. This ensures that the final cast product has a smooth and clean surface.

- Foundry abrasives: Silica sand is also used as an abrasive material in various foundry processes, such as grinding, polishing, and surface finishing of castings.

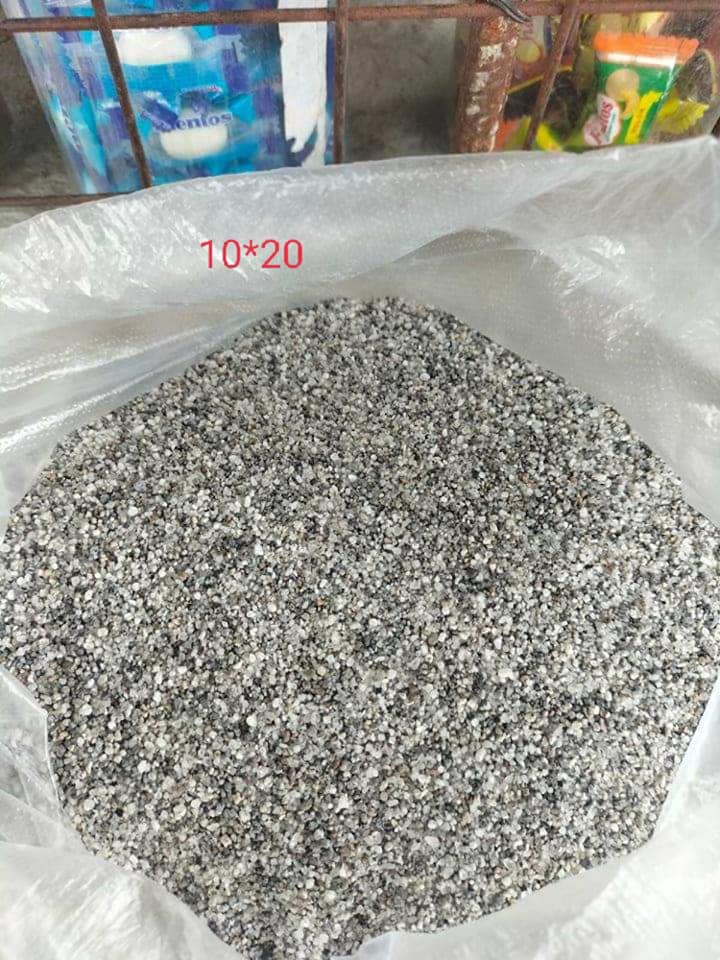

When selecting silica sand for foundry use, it is essential to choose a high-quality material with the right particle size distribution, shape, and chemical composition. This ensures optimal performance in mold making, core making, filtration, and abrasive applications.

Richson’s Trading: Your Trusted Partner

Richson’s Trading stands out as a reliable supplier of silica sand in the Philippines, committed to delivering superior quality products tailored to meet the unique requirements of each industry. With a focus on customer satisfaction and quality assurance, Richson’s ensures consistency and reliability in every batch of silica sand supplied.

Quality Assurance:

Richson’s Trading adheres to stringent quality control measures throughout the sourcing, processing, and distribution stages to guarantee the purity, consistency, and adherence to industry standards of its silica sand products.

Customized Solutions:

Recognizing the diverse needs of its clientele, Richson’s Trading offers customized solutions and blends to optimize the performance of silica sand in specific applications. Whether it’s fine, medium, or coarse-grade silica sand, Richson’s provides tailored products to meet varying project requirements.

Sustainable Sourcing:

Richson’s Trading prioritizes sustainable sourcing practices, ensuring responsible extraction and processing of silica sand to minimize environmental impact. By implementing eco-friendly initiatives and adhering to regulatory guidelines, Richson’s remains committed to preserving natural resources for future generations.

As the demand for silica sand continues to grow across industries, Richson’s Trading stands at the forefront, providing premium quality products and unparalleled service to its customers in the Philippines. With a dedication to excellence, sustainability, and innovation, Richson’s remains the preferred choice for all silica sand needs, driving progress and prosperity across diverse sectors. Choose Richson’s Trading as your trusted partner and unlock the full potential of silica sand in your endeavors.